Welcome to RF & Microwave Division of

SLTL Group

Manufacturer & Exporter of Microwave Absorbers, Radar Absorbent Materials, Shielded Anechoic Chambers, Dielectric Materials, and EMI/EMC Test Ranges for both Civil and Defence needs. Major customers include Aerospace & Defense, Electronic, Telecom, and Automotive Industries – A Complete Line of standard and customized Microwave Absorbers.

Technologies We Serve

We are Continuously giving our services to various fields

Electronic Industries

Telecom Industries

Automotive Industries

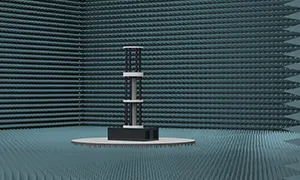

Anechoic Chambers

Call us today at +91-90-9907-1094 or Email us at [email protected]

Want to tell us something? Got a business query? Say Hello!News & Events

Empowering the Selfless Superheroes!

— SLTL Group - RF & Microwave Division (@sltlrf) November 19, 2022

Covering the range of solutions from #Acoustic to #Photonics to #Stealth, team #SLTL #RF has been working tirelessly to thrive the modern-day warfare.#AtmanirbharBharat #Aerospace #defence #PathToPride #IndianArmy #IndianNavy #India pic.twitter.com/teFAZtRq5U

Certificates

NABL Certified RF shielded Door

Download Corporate eBrochure

Download+

Employees

%

Yearly R&D

+

Awards

+

Patents

Our Latest Works

Radar Absorbent Material Installed on

INS KOLKATA

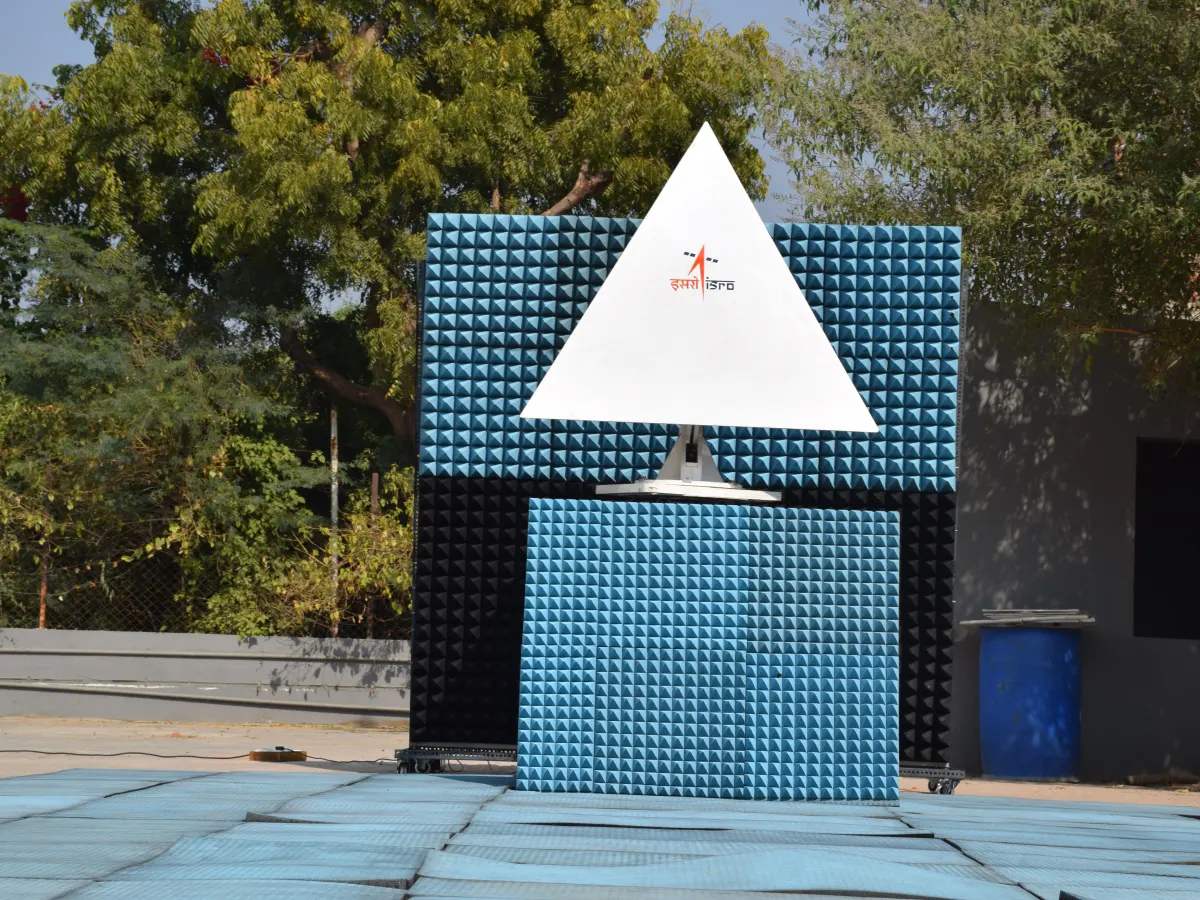

ISRO's Corner Reflector Radome

FOR MAITRI-BHARATI PROJECT AT ANTARCTICA

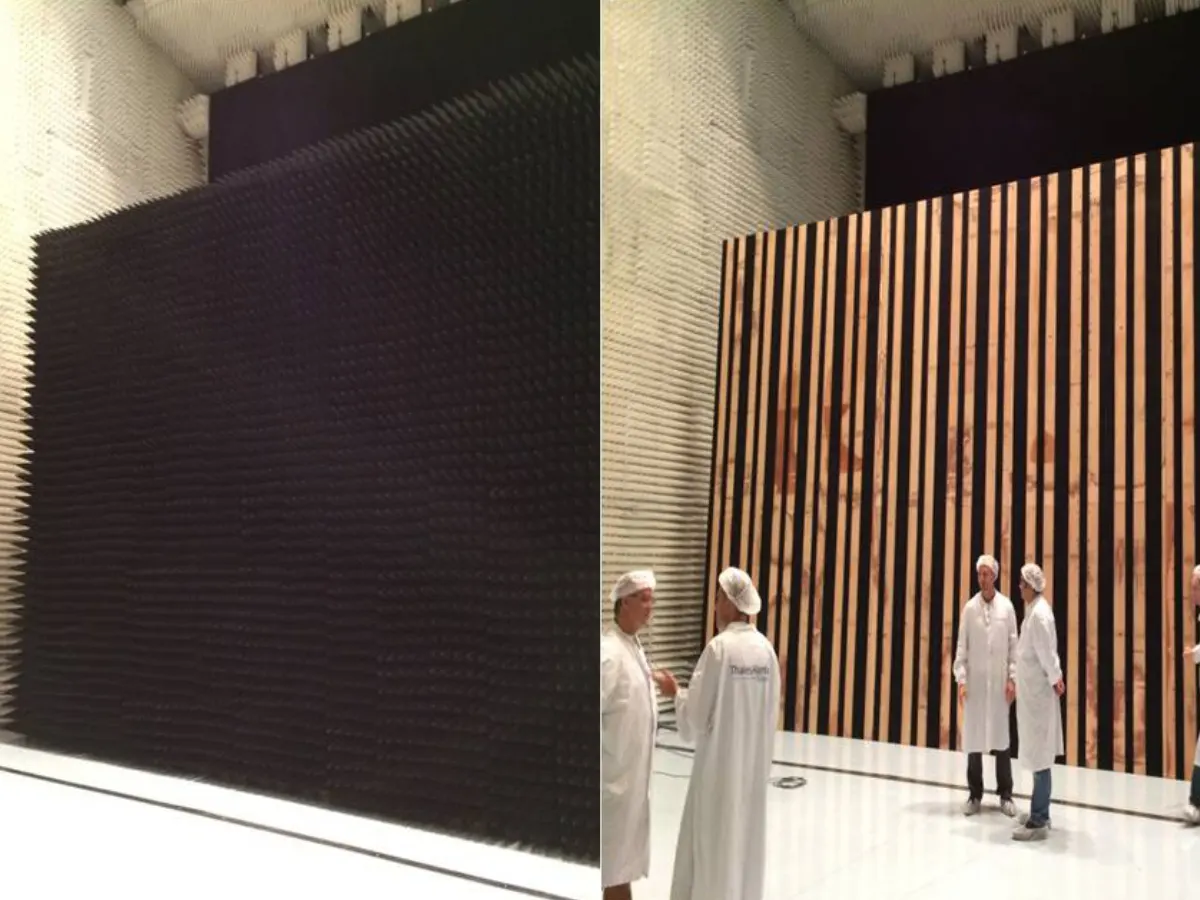

SLTL Clean Room Absorbers Installed at

EUROPEAN SPACE AGENCY THALES ALENIA SPACE

Radar Absorbent Material Installed on

INS KOCHI

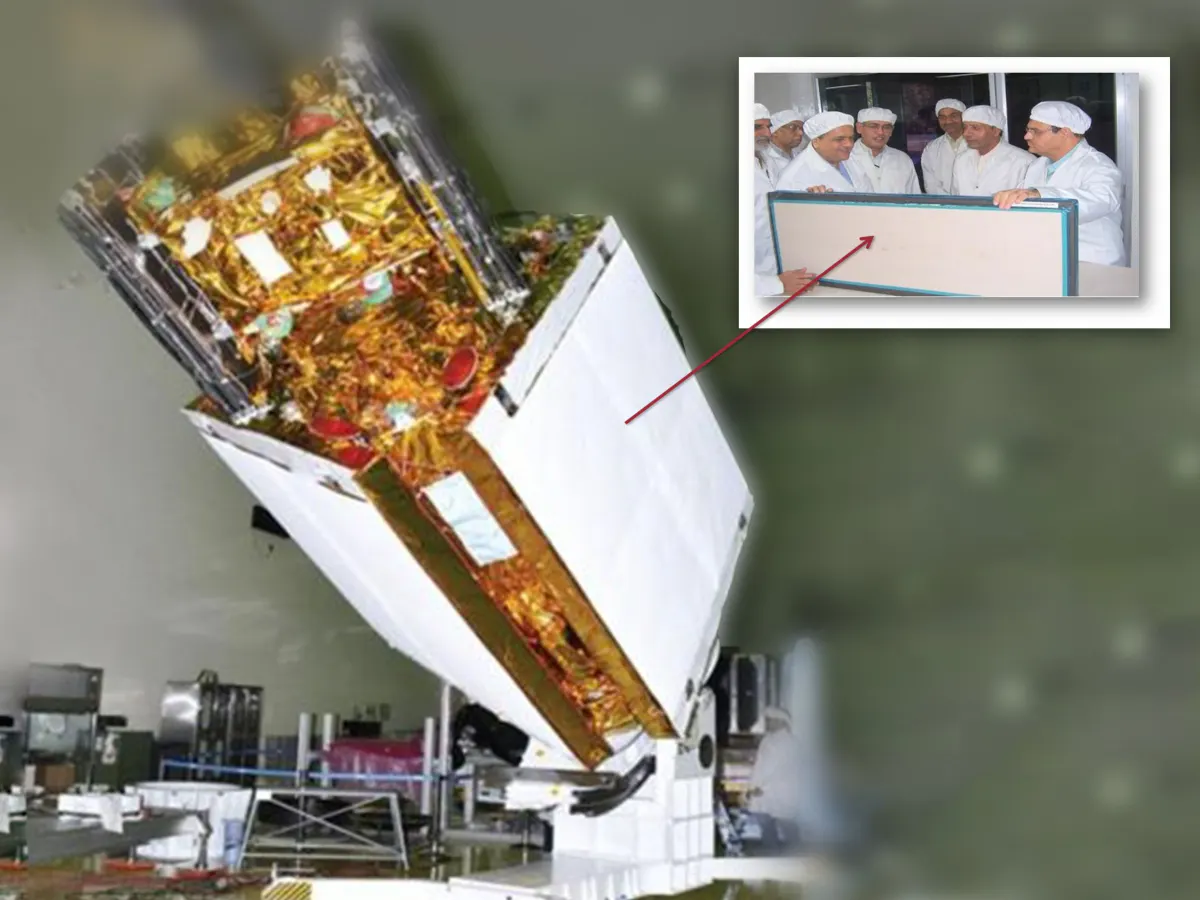

SLTL Group’s Advanced Technology Contribution

TO 24 x 7 RISAT-1 SATELLITE

SLTL Radar Absorbent Material Installation in

ITALIAN NAVY (FINCANTIERI)